01 Product Introduction

The E-Coating conductive rubber with the primer coating process is a kind of conductive rubber with special process and structure, which is very suitable for the application of small-sized extruded rubber strips. Its high electrical conductivity and thin conductive layer not only have a high level of EMI shielding effectiveness but also possess good electrochemical stability. The unique primer coating process can ensure the wear resistance, corrosion resistance reliability of the surface coating, as well as the uniform and consistent aesthetic characteristics. The inner core of the E-Coating conductive rubber with the primer coating process is a non-conductive elastomer, which still has good compression and rebound characteristics even in the case of a very small size. It is an excellent choice for environmental sealing and electromagnetic shielding of products with small sizes and compact structures. The cost of the non-conductive elastomer is much lower than that of the conductive elastomer, and at the same time, the metal coating on the surface of the product is very thin. Therefore, the E-Coating product also has great market competitiveness in terms of cost.

C7006, with an Ag/Ni conductive layer coated on the surface, its excellent electrical conductivity achieved by the primer coating process makes it more suitable for occasions with high requirements for shielding performance. It is mainly applied in the fields of national defense, military industry, and automation.

02 Product Features

① The elastic inner layer does not contain metal fillers, ensuring optimal compression performance and aging performance.

② The conductive particles exist only in the outer coating layer, so it has excellent electrical conductivity.

③ The ultra-thin conductive layer greatly reduces the required silver content.

④ Through a special coating process, the cost of precious metals is effectively saved without reducing the electrical conductivity and shielding performance.

⑤ Compared with the elastomer filled with a solid substance throughout, the attenuation performance does not decrease under full compression force.

⑥ Extremely low compression force and anti-deformation ability.

⑦ Due to the flexibility in manufacturing and the characteristic of rapid response to customer customization, an effective alternative solution can be provided in a very short time.

03、Technical Parameters

| NQ- C7006 | |||

| 典型性能Typical Performance | 导电材料 | 非导电材料 | 测试标准 |

| 基材substrate | 硅胶silicone | R3000 | – |

| 填料Filler | Ag/N | – | – |

| 厚度(mm)Thickness | 0.05 | – | |

| 密度(g/cm3)Density | 2.8 | 1.2 | ASTM D792 |

| 硬度(Shore A)Hardness | 60 | 55 | ASTM D2240 |

| 体积电阻率(Ohm-cm)Volume resistivity | 0.004 | – |

MIL-DTL-

83528C |

| 500M | 100 | – | MIL-DTL-

83528C |

| 屏蔽效能Shielding Effectiveness(dB) 2G | 95 | R3000 | |

| 10G | 90 | – | |

| 工作温度(°C)Operating temperature | -55~+160 | ASTM D1329 | |

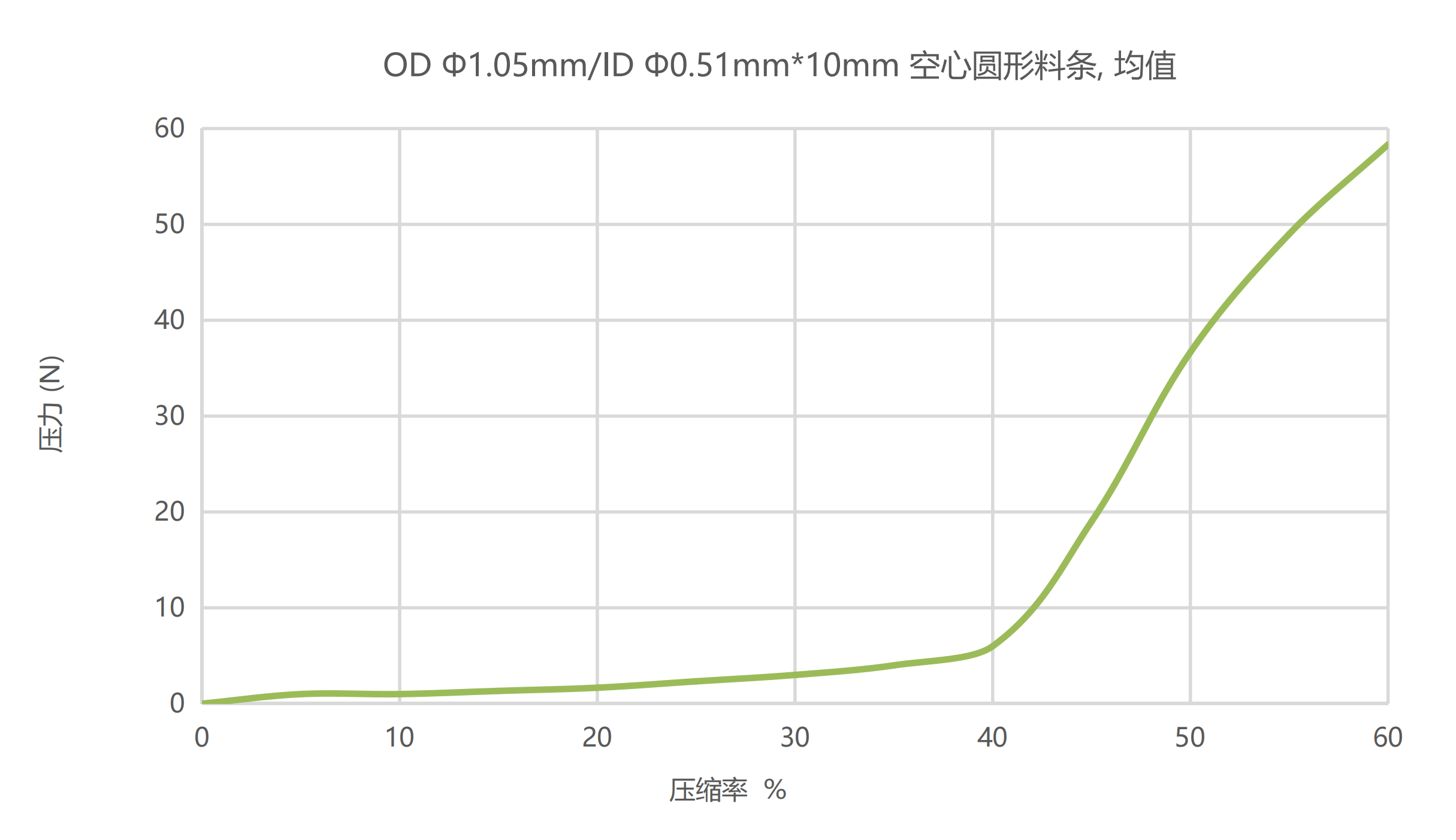

04、Pressure-deformation curve