01 Product Introduction

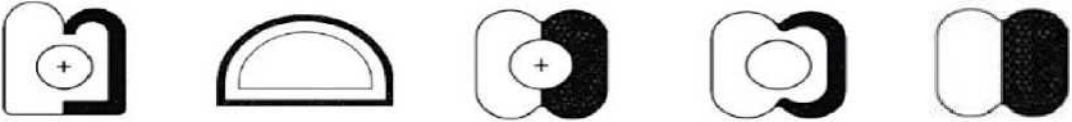

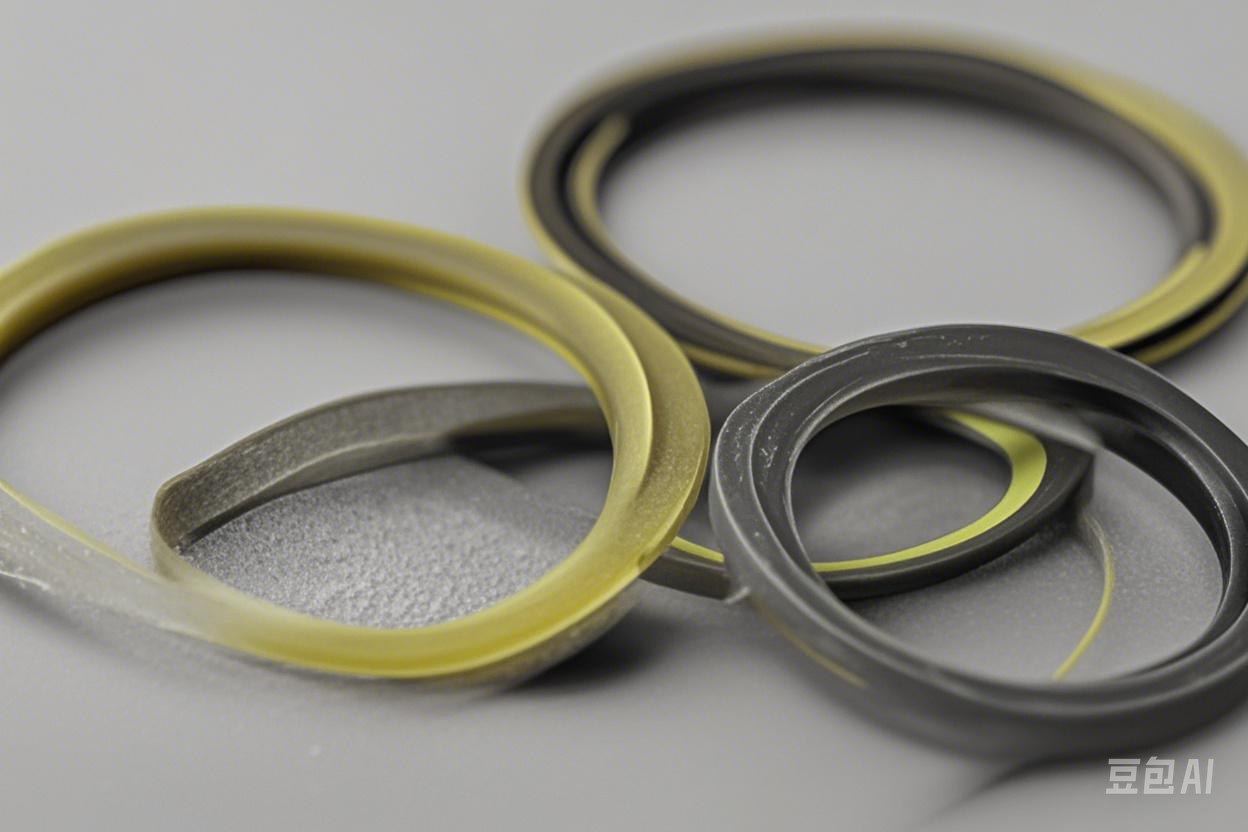

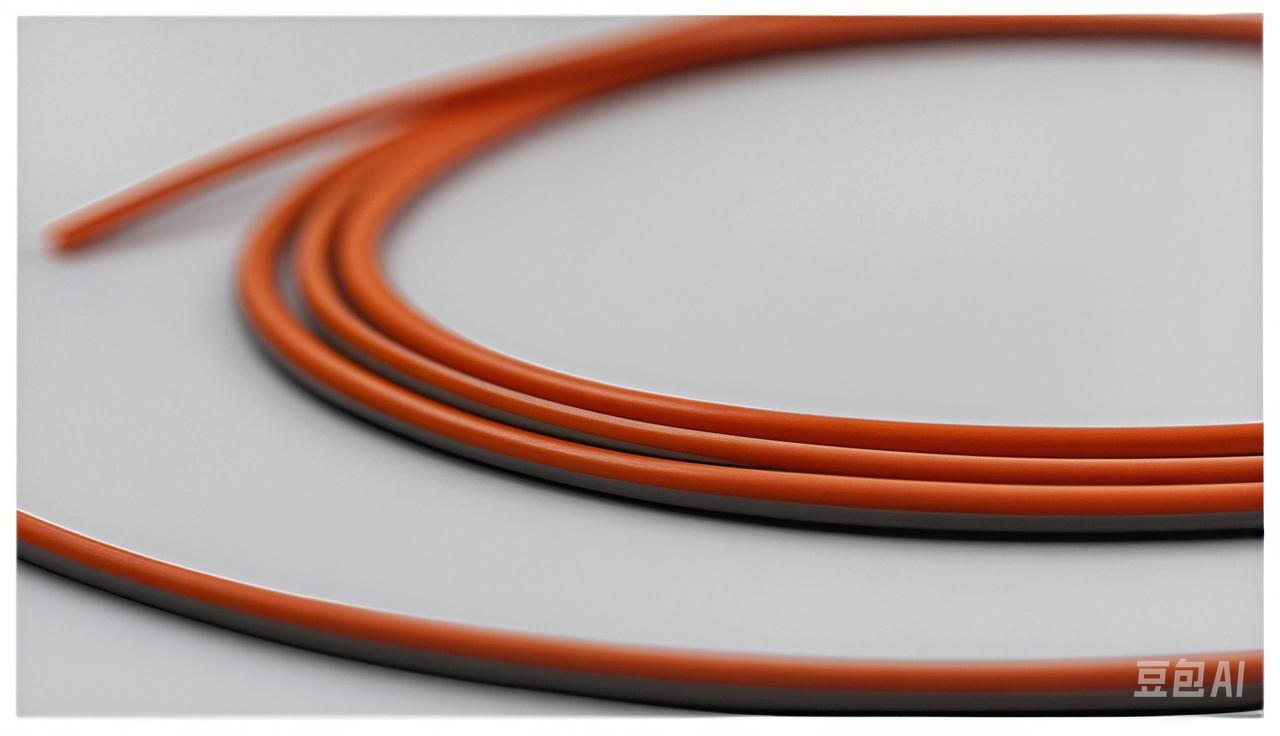

The co-extruded conductive rubber is a new type of polymer material that is compounded and extruded by using a co-extrusion mold with omnidirectional conductive rubber and non-conductive silicone rubber. It has good electrical conductivity and shielding ability. When matched with appropriate groove dimensions, it can also achieve excellent waterproof and dustproof effects. The highest protection level can reach IP68. It is resistant to oil and high temperature, and the manufacturing cost is low.

NQ-OE6009 is obtained through precise extrusion molding using CE5009(Fluorosilicone Conductive Rubber) & R9000 (Fluorosilicone Non-conductive Rubber) , and it has both excellent shielding effectiveness and environmental sealing functions.

① 02 Product Features

① With a reasonable matching of the shell design, high shielding effectiveness can be achieved, and the absorption can reach up to 100dB in the 10GHz frequency band.

② The environmental sealing performance can reach up to IP68 at the highest.

③ It has a wide applicable temperature range and can keep working even under extreme temperatures – generally ranging from -55°C to +170°C, and can also meet the requirements of special temperature applications.

④ Low outgassing

⑤ An effective cost solution

03、Technical Parameters

| Typical Performance | Conductive material | Non-conductive material | Testing Standard |

| Material type | CE5009(silicone)

|

R9000 (Fluorosilicone silicone Conductive Rubber)

|

– |

| Filler | Ag/Al

|

– | – |

| Colour | Blue | Black | |

| Density(g/cm3) | 2.2

|

1.2 | ASTM D792

|

| Volume resistivity(Ohm-cm) | 0.012 | – | MIL-DTL-

83528C

|

| Hardness(Shore A) | 60 | 60 | ASTM D2240

|

| Tensile Strength (PSI) | 120 | 600 | ASTM D412

|

| Elongation at Break (%) | 120 | 300 | ASTM D412

|

| Tear Strength (PSI) | 30 | 60 | ASTM D624

|

| Shielding Effectiveness(dB) | 100(500M) | – | MIL-DTL-

83528C

|

| 100(2G) | – | ||

| 100(10G) | – | ||

| Operating temperature(°C) | -55~+200

|

ASTM D1329 | |