01 Product Introduction

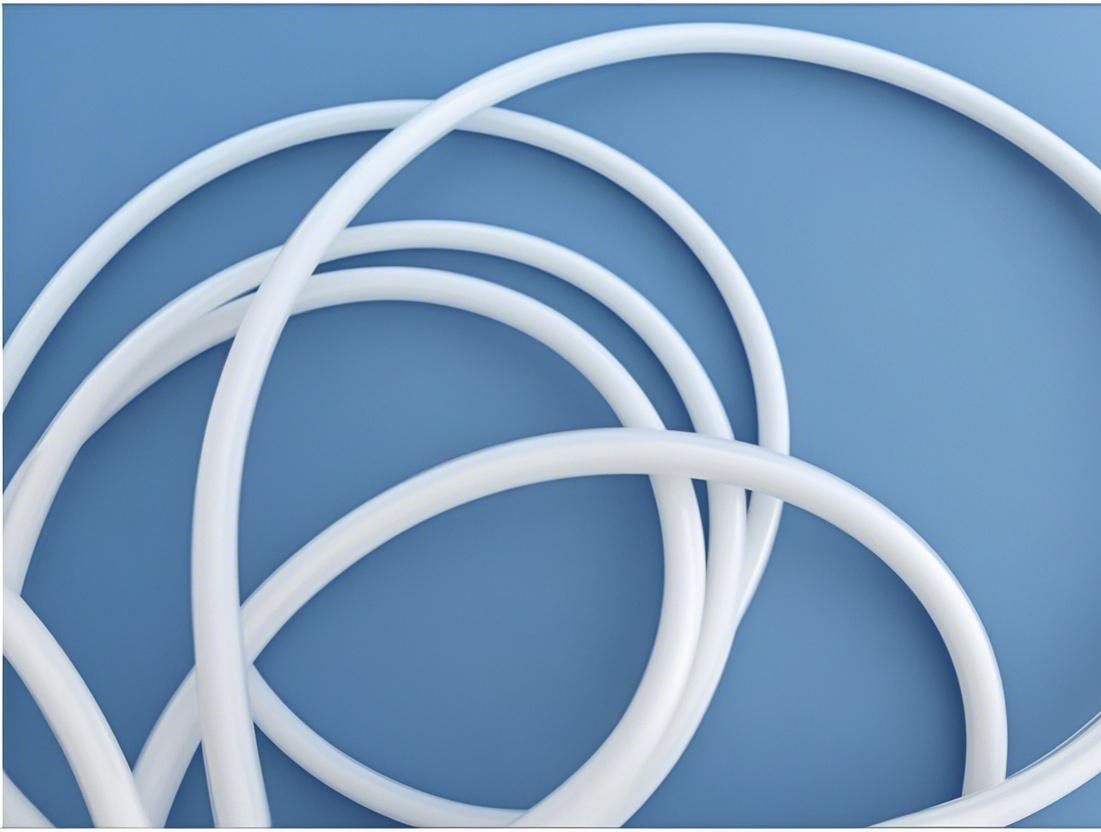

The all-round conductive rubber is a material made by compounding through a series of complex processing techniques such as mixing and vulcanization. It uses ordinary silicone rubber as the base material and is mixed with conductive powder with excellent electrical conductivity. It perfectly combines the flexibility of the silicone rubber itself with the high electrical conductivity of the conductive particles. It can not only meet the requirements of electrical grounding and EMI shielding, but also achieve environmental sealing. Among them, the types of conductive particles include silver-plated aluminum, silver-plated glass, silver-plated nickel, silver-plated copper, nickel-plated aluminum, and nickel-coated graphite, etc. The elastomer base material is mainly silicone rubber or fluorosilicone rubber.

CE5015 is a kind of silver (Ag)-filled conductive silicone rubber, which has excellent electrical conductivity. It features high shielding effectiveness and strong corrosion resistance, which can greatly improve the reliability and service life of products.

① Ultra-low resistance and superior shielding performance

② The environmental sealing performance can reach up to IP68

③ It has a wide temperature application range and can maintain operation even at extreme temperatures – usually from -55°C to +170°C, and can also meet the requirements of special temperature applications

④ Excellent mechanical properties, softness, and long-term durability

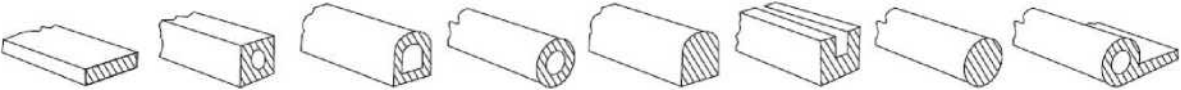

⑤ Sheet materials, die-cut products, compression-molded products, extruded strips or profiles can be provided。

03、Technical Parameters

| Model | NQ-CE5015 | |

| Typical Performance | Test results | Test standard |

| Material type | silicone | N/A

|

| Filler | Ag

|

N/A

|

| Colour | Beige | N/A

|

| Density(g/cm3) | 4.3 | ASTM D792 |

| Volume resistivity(Ohm-cm) | 0.002 | MIL-DTL-

83528C

|

| Hardness(Shore A) | 70 | ASTM D2240 |

| Tensile Strength (PSI) | 150 |

ASTM D412

|

| Elongation at Break (%) | 100 |

ASTM D412

|

| Tear Strength (PSI) | 30 | ASTM D624 |

| Shielding Effectiveness(dB) | 115(500M) | MIL-DTL-

83528C

|

| 120(2G) | ||

| 120(10G) | ||

| Operating temperature(°C) | -55~+170

|

ASTM D1329 |