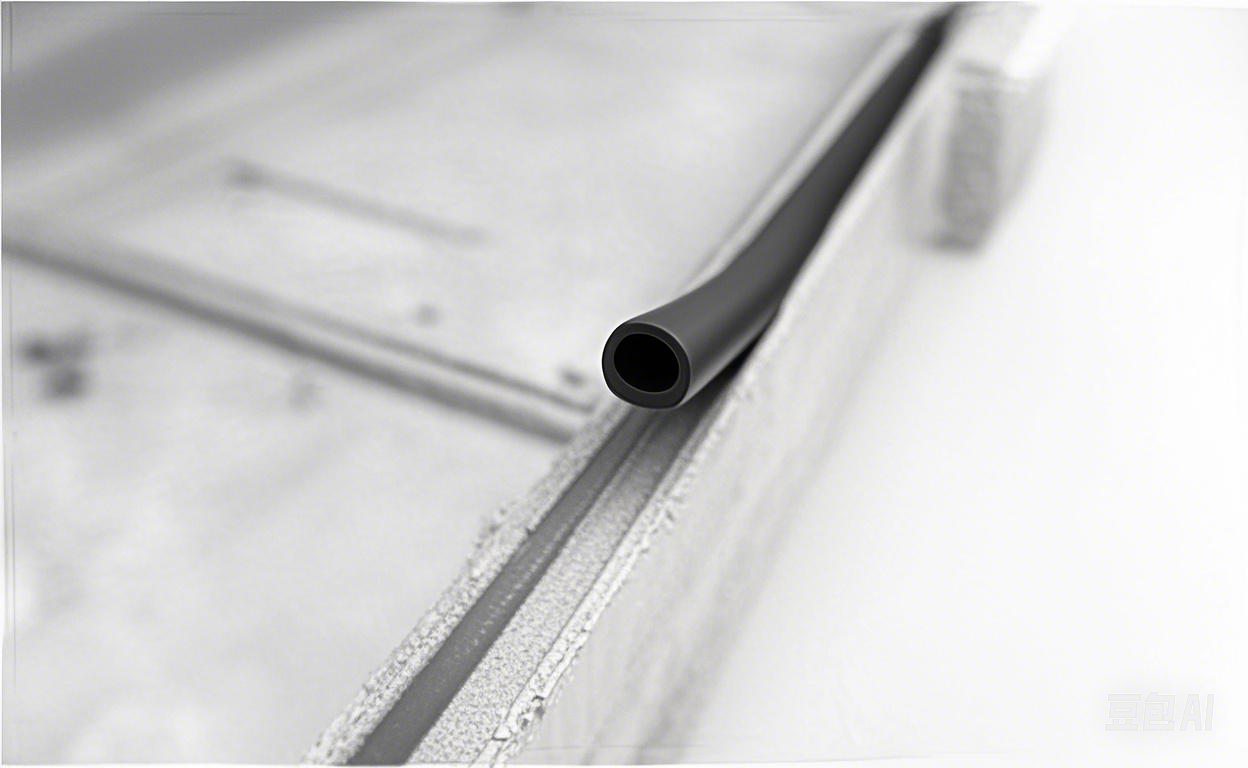

The natural color of CE900370 is made of fluorosilicone rubber as the base material, which is mixed with conductive particles having good electrical conductivity. It is a compound formed through a series of complex processing techniques such as mixing and curing. It is a perfect combination of the flexibility of fluorosilicone rubber and the high electrical conductivity of the conductive particles. It is not only suitable for conductive grounding and EMI shielding, but also an ideal choice for achieving environmental sealing.

The filler of the natural color of CE900370 is nickel-coated graphite, and its base material is fluorosilicone rubber. It has excellent electrical conductivity, and its high shielding characteristics and high corrosion resistance can greatly improve the reliability and service life of the product. It is suitable for commercial and consumer electronics applications.① Ultra-low resistance and superior shielding performance

② The environmental sealing performance can reach up to IP68

③ It has a wide temperature application range and can maintain operation even at extreme temperatures – usually from -55°C to +170°C, and can also meet the requirements of special temperature applications

④ Excellent mechanical properties, softness, and long-term durability

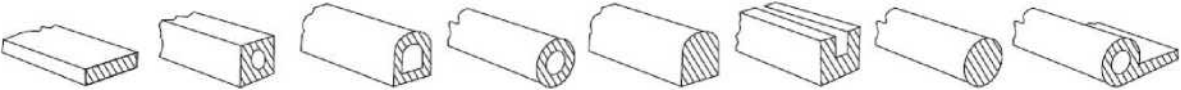

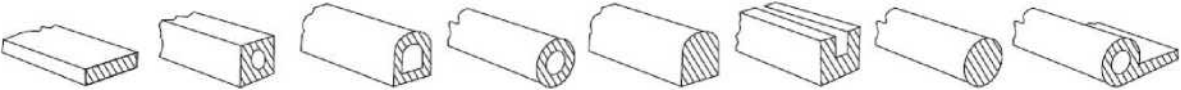

⑤ Sheet materials, die-cut products, compression-molded products, extruded strips or profiles can be provided。

03、Technical Parameters

| Model |

NQ-CE900370 |

| Typical Performance |

Test results |

Test standard |

| Material type |

fluorosilicone |

N/A

|

| Filler |

NI/C

|

N/A

|

| Colour |

Black |

N/A

|

| Density(g/cm3) |

2 |

ASTM D792 |

| Volume resistivity(Ohm-cm) |

0.08 |

MIL-DTL-

83528C

|

| Hardness(Shore A) |

70+/-7 |

ASTM D2240 |

| Tensile Strength (PSI) |

135 |

ASTM D412

|

| Elongation at Break (%) |

50-200 |

ASTM D412

|

| Tear Strength (PSI) |

30 |

ASTM D624 |

| Shielding Effectiveness(dB) |

105(500M) |

MIL-DTL-

83528C

|

| 100(2G) |

| 100(10G) |

| Operating temperature(°C) |

-55~+170

|

ASTM D1329 |