Properties of Conductive Elastic Rubber

Conductive elastic rubber is a functional material that combines both electrical conductivity and elasticity. It is typically composed of a rubber matrix compounded with conductive fillers. This material finds extensive applications in various fields such as electronics, electrical engineering, aerospace, etc. Its unique properties make it an ideal choice for many special occasions. The following will provide a detailed introduction to the main properties of conductive elastic rubber.

- Electrical Conductivity Electrical conductivity is one of the core properties of conductive elastic rubber. By adding metal powders (such as silver, copper, nickel, etc.), carbon-based fillers (such as carbon black, graphite, carbon nanotubes, etc.) or other conductive materials, the rubber matrix acquires good electrical conductivity. Its electrical conductivity can be adjusted according to the type, content and distribution of the fillers, thus meeting different conductivity requirements. For example, when high electrical conductivity is required, the content of metal fillers can be increased; while for some applications where weight is a concern, carbon-based fillers can be selected to balance the electrical conductivity and weight. The volume resistivity of conductive elastic rubber usually ranges from \(10^{-3}\) to \(10^{3}\Omega\cdot cm\), and it has stable electrical conductivity, which can play the roles of electrical connection and electromagnetic shielding in the circuit.

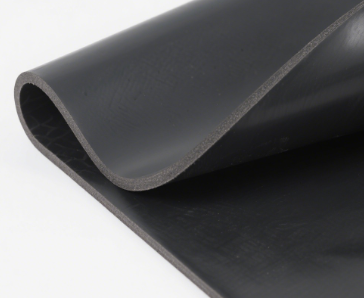

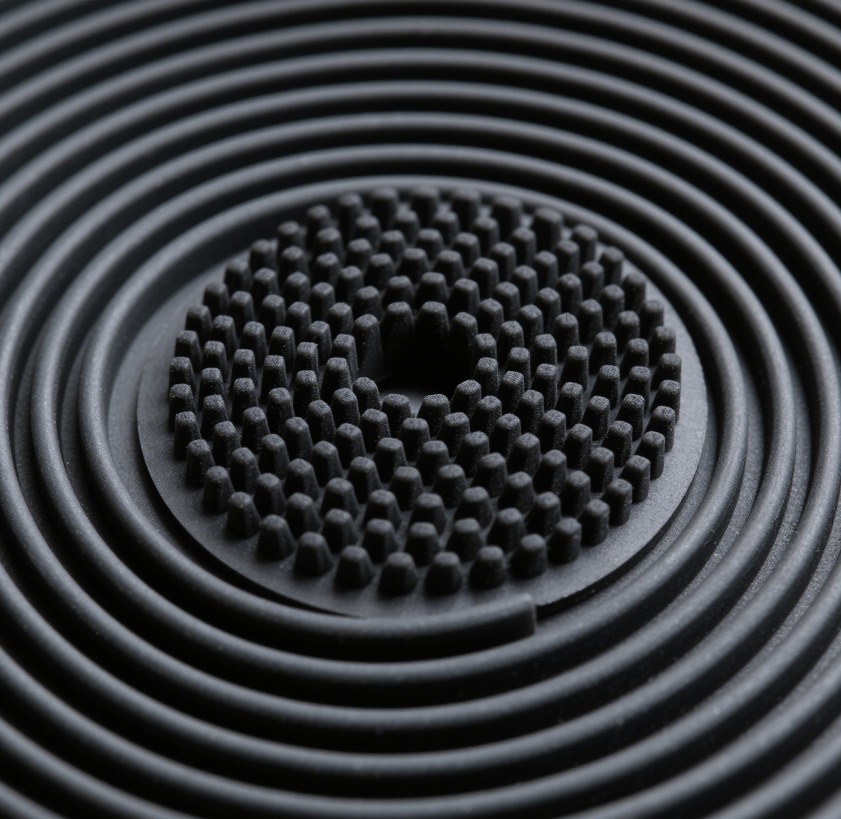

- Elasticity and Flexibility Inheriting the elastic characteristics of the rubber matrix, conductive elastic rubber has good elastic deformation ability and recoverability. When subjected to external forces, it can undergo large elastic deformation, and when the external forces are removed, it can quickly return to its original shape. Its elastic modulus is relatively low, generally between 0.1 and 10 MPa, which enables it to adapt to various complex interfaces and shapes and perform excellently in applications such as sealing and shock absorption. At the same time, its good flexibility makes it less likely to break in dynamic environments such as bending and twisting, improving the service life and reliability of the material.

III. Good Sealing Performance Due to its elasticity and flexibility, conductive elastic rubber can closely fit the contact surface and fill the gaps when squeezed, thus achieving a good sealing effect. This sealing performance can not only prevent the leakage of liquids and gases, but also block the entry of dust, impurities, etc. into the interior of the equipment, protecting electronic components and other parts from the influence of the external environment. In the aerospace, automotive and other fields, where the requirements for the sealing performance of equipment are extremely high, this characteristic of conductive elastic rubber makes it an important choice of sealing material.

- Electromagnetic Shielding Performance The conductive fillers in the conductive elastic rubber form a conductive network, which can reflect, absorb and attenuate electromagnetic waves, thus playing the role of electromagnetic shielding. It can effectively suppress electromagnetic interference, protect electronic equipment from the influence of external electromagnetic waves, and at the same time prevent the electromagnetic waves generated by the equipment itself from leaking, avoiding interference with the surrounding environment. Its electromagnetic shielding effectiveness is related to factors such as the type, content, distribution of the conductive fillers and the structure of the rubber matrix. Through reasonable formulation design and preparation process, conductive elastic rubber materials that meet different electromagnetic shielding requirements can be obtained.

- Environmental Resistance (1) Temperature Resistance Conductive elastic rubber has a certain temperature resistance range, and different combinations of rubber matrices and fillers enable it to adapt to different temperature environments. For example, silicone rubber-based conductive elastic rubber has good high-temperature resistance and can be used in the temperature range of -50°C to 200°C or even higher; while nitrile rubber-based conductive elastic rubber performs better in terms of low-temperature resistance and oil resistance. In a high-temperature environment, it is not prone to decomposition and aging, and maintains good elasticity and electrical conductivity; in a low-temperature environment, it can still maintain a certain degree of flexibility and will not become brittle and crack due to low temperature. (2) Chemical Corrosion Resistance It has a certain degree of corrosion resistance to a variety of chemical media, such as acids, alkalis, salt solutions, oils, etc. This is because the rubber matrix itself has a certain chemical stability, and after surface treatment, the conductive fillers can also improve their corrosion resistance in chemical media. In harsh environments such as the chemical industry and the marine environment, conductive elastic rubber can work stably for a long time without being eroded by chemical media. (3) Aging Resistance During long-term use, conductive elastic rubber will be affected by factors such as ultraviolet rays, oxygen, humidity, etc. and undergo aging. However, by adding anti-aging agents, adopting appropriate processing techniques and other methods, its aging resistance can be significantly improved. For example, adding ultraviolet absorbers can reduce the damage of ultraviolet rays to the rubber matrix and extend the service life of the material.

- Processability Conductive elastic rubber has good processability and can be made into various shaped products through conventional rubber processing techniques such as compression molding, extrusion, injection molding, etc., such as sealing rings, gaskets, conductive connectors, etc. During the processing process, the formulation can be adjusted and the process can be optimized according to different product requirements to obtain the required performance and dimensional accuracy. In addition, it can also be compounded with other materials, such as combining with metals, plastics, etc. to form multifunctional composite materials.

VII. Light Weight Compared with traditional conductive materials such as metals, conductive elastic rubber has a relatively low density, usually between 1.0 and 2.0 g/cm³, and is relatively light in weight. This characteristic is of great significance in weight-sensitive fields such as aerospace and electronic equipment, as it can reduce the overall weight of the equipment and improve energy utilization efficiency.

In conclusion, conductive elastic rubber has a variety of properties such as adjustable electrical conductivity, good elasticity and flexibility, excellent sealing performance, outstanding electromagnetic shielding performance, strong environmental resistance, good processability and light weight. These properties make it widely used in fields such as electronics, electrical engineering, aerospace, automotive, and chemical industry. With the continuous development of science and technology, the performance requirements for conductive elastic rubber are also constantly increasing, and it will play an important role in more fields in the future.