Analysis of the Technology of Conductive Rubber with Driving Performance

- Introduction

In today’s era of rapid technological development, new functional materials are constantly emerging, and conductive rubber with driving performance is one of the materials that has attracted much attention. It combines the flexibility of rubber and electrical conductivity, showing great application potential in many fields, such as smart devices, electronic devices, sensors, etc. This article will conduct an in-depth analysis of the relevant technologies of conductive rubber with driving performance.

- Definition and Characteristics of Conductive Rubber with Driving Performance

(1) Definition

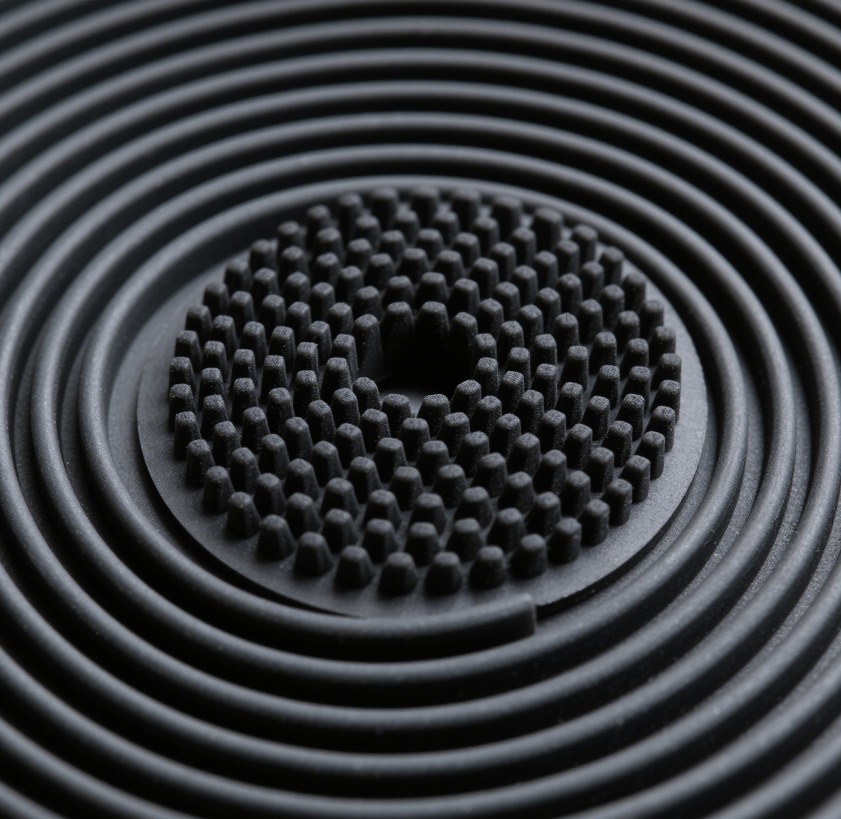

Conductive rubber with driving performance refers to a composite material in which conductive fillers are added to the rubber matrix to endow it with electrical conductivity and certain driving characteristics at the same time. When subjected to external stimuli such as electrical signals and temperature changes, it can produce corresponding deformations or mechanical movements to achieve specific functions.

(2) Characteristics

Good electrical conductivity: By reasonably selecting the type and content of conductive fillers, the rubber material can have stable electrical conductivity to meet the needs of different circuit systems. Common conductive fillers include carbon black, metal powders (such as silver powder and copper powder), carbon nanotubes, graphene, etc. These fillers form a conductive network in the rubber matrix to realize the transmission of electrons.

Excellent flexibility and elasticity: It inherits the inherent characteristics of rubber materials and can maintain stable performance within a large deformation range, adapting to complex usage environments. Even if it is squeezed, bent or stretched by external forces, it can still return to its original shape, and the electrical conductivity will not be significantly affected.

Response characteristics: It has a certain response ability to external stimuli such as electrical signals, temperature, and pressure. For example, under electrical drive, it may undergo deformations such as expansion, contraction or bending. This characteristic makes it can be used as the core material of actuators or sensors.

Processability: It can be made into products of various shapes and sizes through traditional rubber processing techniques, such as mixing, vulcanization, and molding, to meet different application requirements.

III. Types and Functions of Conductive Fillers

(1) Carbon Black

Carbon black is a commonly used conductive filler, which has the advantages of low cost and wide sources. It can form a conductive path in the rubber matrix and improve the electrical conductivity of the material. Parameters such as the particle size, structure, and surface area of carbon black have a significant impact on the electrical conductivity. Generally speaking, the smaller the particle size, the higher the structure, and the larger the surface area, the easier it is to form a conductive network, and the better the electrical conductivity.

(2) Metal Powders

Metal powders such as silver powder and copper powder have extremely high electrical conductivity. Adding them to rubber can endow the material with excellent electrical conductivity. However, metal powders are costly, and their dispersibility in the rubber matrix is poor, and agglomeration is likely to occur, which affects the mechanical properties of the material. In addition, metal powders are prone to oxidation, leading to a decrease in electrical conductivity. Therefore, measures such as surface treatment need to be taken to improve their stability.

(3) Carbon Nanotubes

Carbon nanotubes have a unique one-dimensional structure and excellent electrical and mechanical properties. A small amount of carbon nanotubes can form an efficient conductive network in the rubber matrix, endowing the material with good electrical and mechanical properties. At the same time, carbon nanotubes also have a high specific surface area and can form a strong interfacial bond with the rubber matrix, improving the overall performance of the material. However, carbon nanotubes are costly, and the problem of dispersibility needs to be solved during the preparation process.

(4) Graphene

Graphene is a two-dimensional carbon material with extremely high electrical and mechanical properties. Adding graphene to rubber can significantly improve the electrical conductivity, thermal conductivity, and mechanical properties of the material. The lamellar structure of graphene can form a continuous conductive network in the rubber matrix, reducing the amount of conductive filler added, thereby maintaining the flexibility and elasticity of the rubber. However, the preparation cost of graphene is high, and the dispersibility and compatibility in the rubber matrix still need further research.

- Preparation Process of Conductive Rubber with Driving Performance

(1) Mixing Process

Mixing is the process of uniformly mixing the rubber matrix with conductive fillers, additives, etc. Commonly used mixing equipment includes open mixers, internal mixers, etc. During the mixing process, parameters such as the mixing temperature, time, and rotation speed need to be controlled to ensure that the conductive fillers are uniformly dispersed in the rubber matrix and a good conductive network is formed.

(2) Vulcanization Process

Vulcanization is the process of cross-linking rubber to form a three-dimensional network structure. Parameters such as the vulcanizing agent, vulcanization temperature, and vulcanization time have an important impact on the mechanical properties and electrical conductivity of the rubber. By reasonably selecting the vulcanization process, the conductive rubber with driving performance can have good physical and mechanical properties and stable electrical conductivity.

(3) Molding Process

The molding process includes compression molding, extrusion molding, injection molding, etc. According to the shape and size requirements of the product, an appropriate molding process is selected. During the molding process, attention needs to be paid to the design and processing accuracy of the mold to ensure the quality and performance of the product.

- Application Fields of Conductive Rubber with Driving Performance

(1) Smart Devices

In smart wearable devices, conductive rubber with driving performance can be used to make flexible sensors and actuators. For example, in wearable electronic bracelets or watches, using its electrical conductivity and driving characteristics, it can monitor human body movements and physiological signals and perform corresponding feedback actions. In the field of smart robots, it can be used as the joint driving material of robots, enabling robots to have more flexible movement capabilities.

(2) Electronic Devices

In flexible electronic devices, such as flexible circuit boards and flexible displays, conductive rubber with driving performance can be used as a conductive connection material and a supporting material. Its flexibility and electrical conductivity can meet the requirements of flexible electronic devices for materials, and it can also realize the driving and control of the devices.

(3) Sensor Field

It can be used to make pressure sensors, temperature sensors, etc. When subjected to pressure or temperature changes, the resistance of the material will change. By detecting the change in resistance, the measurement of pressure or temperature can be realized. This type of sensor has the advantages of high sensitivity, fast response speed, and good flexibility, and can be applied in medical, industrial monitoring and other fields.

(4) Other Fields

In the fields of aerospace, automotive manufacturing, etc., conductive rubber with driving performance also has certain application prospects. For example, in aerospace, it can be used to make flexible antennas and sensors for aircraft; in automotive manufacturing, it can be used to make conductive seals and sensors for automobiles.

- Research Status and Development Trends of Conductive Rubber with Driving Performance

(1) Research Status

At present, the research on conductive rubber with driving performance at home and abroad mainly focuses on the modification of conductive fillers, the selection of rubber matrices, the optimization of the preparation process, and the performance characterization. Through methods such as surface treatment of conductive fillers, development of new rubber matrix materials, and improvement of the preparation process, the electrical conductivity, mechanical properties, and driving performance of the material are continuously improved. At the same time, in-depth research on the response mechanism and failure mechanism of the material provides theoretical support for the design and application of the material.

(2) Development Trends

High-performance: With the development of science and technology, the performance requirements for conductive rubber with driving performance are getting higher and higher. In the future, efforts will be made to improve the electrical conductivity, mechanical strength, response speed, and stability of the material to meet the application requirements of high-end fields.

Multifunctional: Develop conductive rubber with driving performance that has multiple functions, such as simultaneously having electrical conductivity, thermal conductivity, wear resistance, aging resistance, etc., so that it can play a better role in complex environments.

Intelligent: Combining with the development trend of intelligent materials, make the conductive rubber with driving performance have functions such as self-diagnosis, self-repair, and self-adaptation, and realize the intelligent application of the material.

Low-cost: Reduce the cost of conductive fillers and improve the efficiency of the preparation process, so that the conductive rubber with driving performance can be applied in a wider range of fields.

VII. Conclusion

As a new type of functional material, conductive rubber with driving performance has good electrical conductivity, flexibility, and driving characteristics, and has broad application prospects in fields such as smart devices, electronic devices, and sensors. With the continuous in-depth research and improvement of the preparation process, its performance will be continuously improved, and the application range will also be continuously expanded. In the future, it is necessary to further strengthen the research on the modification of conductive fillers, the optimization of rubber matrices, the innovation of the preparation process, and the performance mechanism, and promote the industrial development of conductive rubber with driving performance.