Applications of Strain-Responsive Conductive Rubber

Strain-responsive conductive rubber is a functional material with unique properties. It combines the flexibility of rubber with electrical conductivity and can respond to external strains (such as stretching, compression, bending, etc.), showing changes in resistance or electrical conductivity. This material has shown broad application prospects in multiple fields, and the following will introduce its main application scenarios in detail.

- Sensor Field

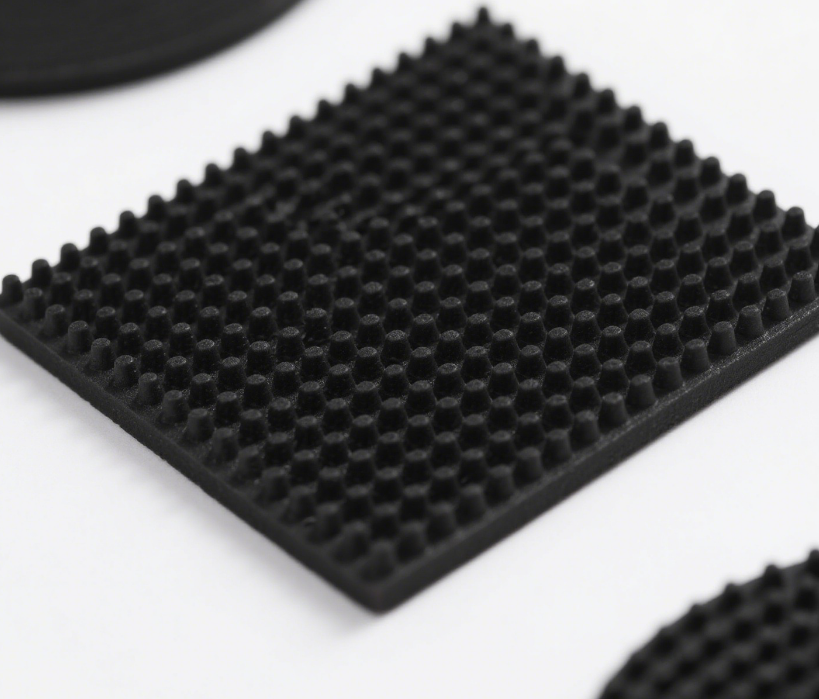

(1) Pressure Sensors

In industrial production, strain-responsive conductive rubber can be used to manufacture high-precision pressure sensors. For example, in machining equipment, installing it at the contact parts of molds or workpieces can monitor pressure changes in real time to ensure machining accuracy and equipment safety. When subjected to pressure, the rubber deforms, and the internal conductive network structure changes, leading to a change in resistance. The magnitude of the pressure can be obtained by measuring the resistance value. Compared with traditional pressure sensors, it has the advantages of good flexibility, low cost, and easy installation, and can be applied to pressure measurement on complex curved surfaces. In the medical field, it can also be used to make medical pressure sensors, such as monitoring human skin pressure, which can be used in rehabilitation aids to help patients better perceive the body pressure distribution and assist in rehabilitation treatment.

(2) Strain Sensors

In the structural health monitoring of bridges, buildings, and other structures, strain sensors made of strain-responsive conductive rubber play an important role. By pasting it on the surface of the structure, when the structure undergoes slight strains due to factors such as loads and temperature changes, the resistance of the sensor will change accordingly. Through data collection and analysis, the stress state of the structure can be grasped in real time, and potential hazards such as structural cracks and deformations can be detected in advance, providing a basis for the safety assessment and maintenance of the structure. This sensor has good durability and environmental adaptability and can work stably for a long time in harsh outdoor environments.

- Smart Wearable Devices

(1) Sports Monitoring Devices

In wearable devices such as smart bracelets and sports watches, strain-responsive conductive rubber can be used to make sports sensors. When users perform sports such as running, swimming, and mountaineering, actions such as muscle stretching and joint bending of body parts will cause the conductive rubber worn on the corresponding parts to generate strain, thus causing a change in resistance. By detecting these changes, the device can monitor the user’s movement posture, exercise intensity, and movement trajectory in real time, and provide users with exercise data records and health suggestions. For example, in a device worn on the wrist, it can monitor the degree of wrist bending to determine whether the user is in a state of typing, holding an object, etc., providing support for intelligent interaction.

(2) Health Monitoring Devices

In the field of health monitoring, strain-responsive conductive rubber can be used to make sensors for heart rate monitoring, respiratory monitoring, etc. By designing it into a flexible patch and attaching it to parts of the human body such as the chest or wrist, when the chest heaves due to the heartbeat or the chest expands and contracts during breathing, the patch will generate strain, which in turn leads to a change in resistance. By analyzing the variation pattern of the resistance signal, physiological parameters such as heart rate and respiratory rate can be accurately obtained, providing a convenient means for telemedicine and home health monitoring. This sensor has good comfort and conformability and will not cause restraint or discomfort to the human body.

III. Flexible Electronic Devices

(1) Flexible Displays

In the technology of flexible displays, strain-responsive conductive rubber can be used as a flexible electrode material. Traditional rigid electrodes cannot meet the deformation requirements of flexible displays such as bending and folding. However, conductive rubber has good flexibility and electrical conductivity and can maintain stable electrical conductivity under bending, stretching, and other states. Applying it to the production of electrodes for flexible displays can realize the flexibility of the display and expand the application scenarios of the display, such as wearable electronic devices and in-vehicle flexible display terminals. In addition, by using its strain-responsive characteristics, flexible displays with touch sensing functions can be developed to achieve more flexible human-machine interaction.

(2) Flexible Circuits

In flexible electronic circuits, strain-responsive conductive rubber can be used to make flexible wires and connecting devices. With the development of flexible electronic technology, higher requirements are put forward for the flexibility and stretchability of circuits. Flexible wires made of conductive rubber can withstand a certain degree of stretching, bending, and twisting and are not easy to break, making them suitable for electronic devices that require frequent movement or deformation, such as flexible robots and foldable electronic devices. At the same time, by using its strain-responsive characteristics, strain sensing functions can also be realized in flexible circuits, and the deformation state of the circuit can be monitored in real time to improve the reliability and intelligence level of the device.

- Automotive Industry

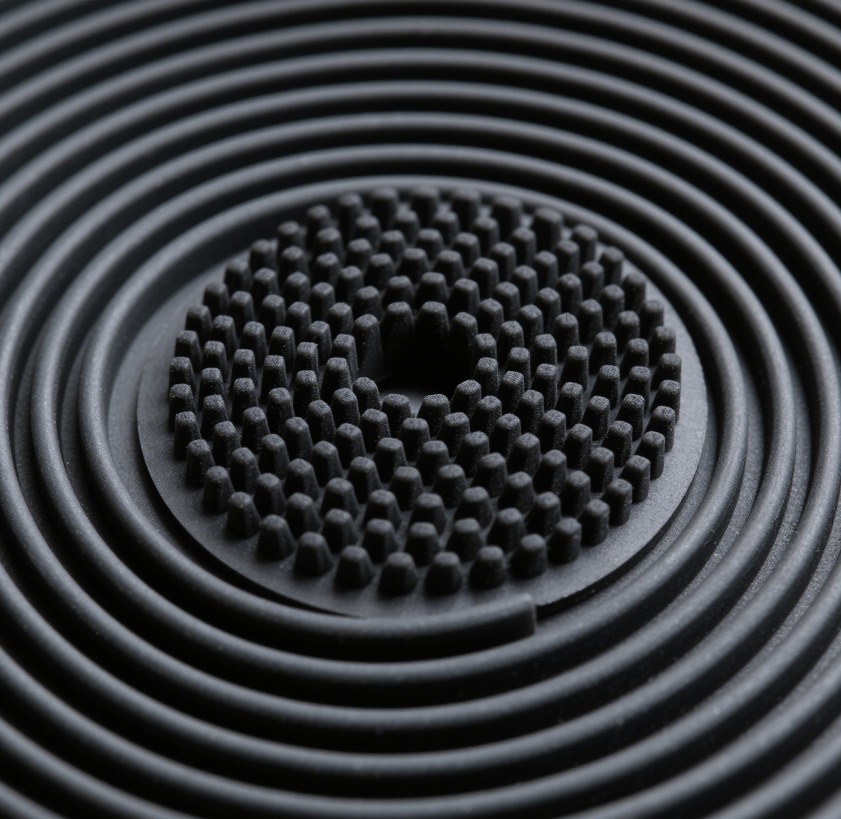

(1) Tire Pressure Monitoring

In automobile tires, strain-responsive conductive rubber can be used to make tire pressure monitoring sensors. By embedding the sensor inside the tire, when the tire pressure changes, the deformation of the tire will cause the conductive rubber to generate strain, thus causing a change in resistance. The resistance signal is transmitted to the in-vehicle system through wireless transmission technology, and the tire pressure can be monitored in real time, reminding the driver to adjust the tire pressure in time to ensure driving safety. This sensor has the advantages of high temperature resistance, wear resistance, and anti-interference and can work stably in the complex driving environment of the automobile.

(2) Seat Pressure Distribution Monitoring

In automobile seats, pressure distribution monitoring sensors made of strain-responsive conductive rubber can be used to monitor the pressure distribution of passengers on the seat in real time. By analyzing the pressure data, it can provide a basis for the design optimization of the seat, improving the comfort and support of the seat. At the same time, in self-driving cars, the position, angle, and other parameters of the seat can also be adjusted according to the passenger’s pressure distribution to provide a more personalized riding experience for passengers.

- Medical Field

(1) Rehabilitation Aids

In rehabilitation medicine, strain-responsive conductive rubber can be used to make rehabilitation aids such as intelligent prosthetics and orthoses. In intelligent prosthetics, installing conductive rubber sensors at the joint parts of the prosthetics, when the patient performs actions such as walking and grasping, the movement of the joints causes the sensors to generate strain, thus generating electrical signals. The movement of the prosthetics is driven through the control system, enabling the prosthetics to better simulate the natural movements of the human body and improving the patient’s self-care ability. In orthoses, the force-bearing situation of the patient’s limbs can be monitored, providing real-time data support for orthopedic treatment and adjusting the correction force and angle of the orthosis.

(2) Wound Monitoring

In medical care, strain-responsive conductive rubber can be used to make wound monitoring patches. By pasting the patch on the surface of the wound, when factors such as skin stretching and changes in exudate during the wound healing process cause the patch to generate strain, the resistance will change accordingly. By monitoring the change of the resistance signal, the healing situation of the wound can be understood in real time, such as whether there are abnormal situations such as infection and bleeding, providing timely diagnostic basis for medical staff and improving the efficiency and quality of wound care.

- Future Development Trends

With the continuous development of materials science, electronic technology, and smart devices, the application prospects of strain-responsive conductive rubber will be even broader. In the future, its development trends mainly include the following aspects:

(1) High Performance

Further improve the electrical conductivity, strain sensitivity, durability, and environmental adaptability of strain-responsive conductive rubber to meet the application scenarios with higher requirements, such as monitoring and sensing in environments with extreme temperatures, high pressures, and strong corrosions.

(2) Multifunctional Integration

Integrate strain-responsive conductive rubber with other functional materials (such as sensors, actuators, energy storage devices, etc.) to develop intelligent composite systems with multiple functions, realizing more complex intelligent control and interaction functions.

(3) Miniaturization and Flexibility

With the development of wearable devices and microelectronic devices, higher requirements are put forward for the miniaturization and flexibility of materials. In the future, efforts will be made to develop thinner, lighter, softer, and stretchable strain-responsive conductive rubber materials to adapt to the design of miniaturized and flexible electronic devices.

(4) Intelligence and Networking

Combined with the Internet of Things, big data, and artificial intelligence technologies, connect strain-responsive conductive rubber sensors to the intelligent network to achieve real-time data collection, analysis, and remote control, providing more intelligent solutions for fields such as smart cities, smart homes, and industrial Internet.

In conclusion, as a functional material with unique properties, strain-responsive conductive rubber has broad application prospects in fields such as sensors, smart wearable devices, flexible electronic devices, the automotive industry, and medicine. With the continuous progress of technology, its application scope will continue to expand, providing strong support for the intelligent and flexible development of various industries.