Development Scheme of Broadband Wave-Absorbing Silicone Rubber

2025/04/18

0

I. Introduction

Against the backdrop of continuous innovation in high-frequency electronic technologies such as 5G communication and radar detection, the operating frequency bands of devices are expanding increasingly. Absorbing materials for a single frequency band can hardly meet the demand any longer. Therefore, the development of broadband wave-absorbing silicone rubber has become the key to solving electromagnetic interference and radiation problems. Thanks to its excellent flexibility, weather resistance, and processing performance, silicone rubber is an ideal matrix for preparing broadband wave-absorbing materials. This scheme will put forward the development strategy of broadband wave-absorbing silicone rubber focusing on aspects such as the wave-absorbing mechanism, material selection, structural design, and process optimization, so as to achieve efficient absorption of electromagnetic waves in multiple frequency bands.

II. Analysis of the Broadband Wave-Absorbing Mechanism

Broadband wave absorption requires the comprehensive utilization of multiple electromagnetic loss mechanisms, including electrical loss, magnetic loss, and interfacial polarization loss. Electrical loss materials (such as carbon-based materials) absorb electromagnetic energy through electron polarization and conductance loss; magnetic materials (such as ferrites and carbonyl iron powder) convert energy relying on hysteresis loss and eddy current loss; and the interfacial polarization between different phases inside the material can cause electromagnetic waves to be reflected, scattered, and dissipated in energy at the interface. The core idea of achieving broadband wave absorption is to reasonably combine wave-absorbing fillers with different loss mechanisms, optimize their dispersion and distribution in the silicone rubber matrix, and construct a synergistic wave-absorbing system.

III. Selection of Key Materials

(1) Silicone Rubber Matrix

Vinyl silicone rubber is selected as the matrix material, and its vinyl content is controlled within the range of 0.1% – 0.2%. This can not only ensure a sufficient addition curing reaction with hydrogen-containing silicone oil under the action of a platinum catalyst to form a stable three-dimensional network structure but also maintain the flexibility and processing performance of the rubber. The temperature resistance range of this matrix material is -60°C – 200°C, which is suitable for a variety of complex environments and provides a basis for the stable performance of broadband wave absorption.

(2) Broadband Wave-Absorbing Fillers

Against the backdrop of continuous innovation in high-frequency electronic technologies such as 5G communication and radar detection, the operating frequency bands of devices are expanding increasingly. Absorbing materials for a single frequency band can hardly meet the demand any longer. Therefore, the development of broadband wave-absorbing silicone rubber has become the key to solving electromagnetic interference and radiation problems. Thanks to its excellent flexibility, weather resistance, and processing performance, silicone rubber is an ideal matrix for preparing broadband wave-absorbing materials. This scheme will put forward the development strategy of broadband wave-absorbing silicone rubber focusing on aspects such as the wave-absorbing mechanism, material selection, structural design, and process optimization, so as to achieve efficient absorption of electromagnetic waves in multiple frequency bands.

II. Analysis of the Broadband Wave-Absorbing Mechanism

Broadband wave absorption requires the comprehensive utilization of multiple electromagnetic loss mechanisms, including electrical loss, magnetic loss, and interfacial polarization loss. Electrical loss materials (such as carbon-based materials) absorb electromagnetic energy through electron polarization and conductance loss; magnetic materials (such as ferrites and carbonyl iron powder) convert energy relying on hysteresis loss and eddy current loss; and the interfacial polarization between different phases inside the material can cause electromagnetic waves to be reflected, scattered, and dissipated in energy at the interface. The core idea of achieving broadband wave absorption is to reasonably combine wave-absorbing fillers with different loss mechanisms, optimize their dispersion and distribution in the silicone rubber matrix, and construct a synergistic wave-absorbing system.

III. Selection of Key Materials

(1) Silicone Rubber Matrix

Vinyl silicone rubber is selected as the matrix material, and its vinyl content is controlled within the range of 0.1% – 0.2%. This can not only ensure a sufficient addition curing reaction with hydrogen-containing silicone oil under the action of a platinum catalyst to form a stable three-dimensional network structure but also maintain the flexibility and processing performance of the rubber. The temperature resistance range of this matrix material is -60°C – 200°C, which is suitable for a variety of complex environments and provides a basis for the stable performance of broadband wave absorption.

(2) Broadband Wave-Absorbing Fillers

- Composite Fillers

- Magnetic – Electrical Loss Composite: Carbonyl iron powder (with a particle size of 5 – 10μm) and carbon nanotubes (with a tube diameter of 10 – 30nm and a length of 1 – 10μm) are compounded at a mass ratio of 3:1. The carbonyl iron powder provides magnetic loss, and the carbon nanotubes construct a conductive network to generate electrical loss. The synergistic effect of the two can cover a relatively wide frequency band. For example, effective absorption can be achieved in both the X band (8 – 12GHz) and the Ku band (12 – 18GHz).

- Two-Dimensional Material Composite: Graphene oxide and MXene are mixed at a ratio of 1:1. The functional groups on the surface of graphene oxide can enhance the interfacial bonding with the matrix. The high electrical conductivity and unique lamellar structure of MXene can extend the propagation path of electromagnetic waves, showing excellent broadband wave-absorbing potential in the C band (4 – 8GHz) to the Ku band.

- Frequency Selective Surface (FSS) Functional Fillers: Metal meshes or FSS fillers with periodic structures are introduced. By designing specific geometric dimensions and arrangement methods, the material can generate resonant absorption in specific frequency bands, which can specifically enhance the absorption effect in a certain frequency band and cooperate with other fillers to achieve broadband coverage.

(3) Additive System - Dispersant: A silane coupling agent (such as γ-methacryloxypropyl trimethoxysilane) is used to modify the surface of the wave-absorbing filler, and the addition amount is 1% – 3%. The coupling agent forms chemical bonds on the surface of the filler, reduces the surface energy of the filler, improves its dispersibility in the silicone rubber matrix, and avoids the decline of wave-absorbing performance caused by agglomeration.

- Plasticizer: 5% – 8% of hydroxyl silicone oil is added as a plasticizer to reduce the viscosity of the rubber compound, improve the processing fluidity, and at the same time enhance the flexibility of the vulcanizate to ensure that the broadband wave-absorbing performance is not affected by the processing process.

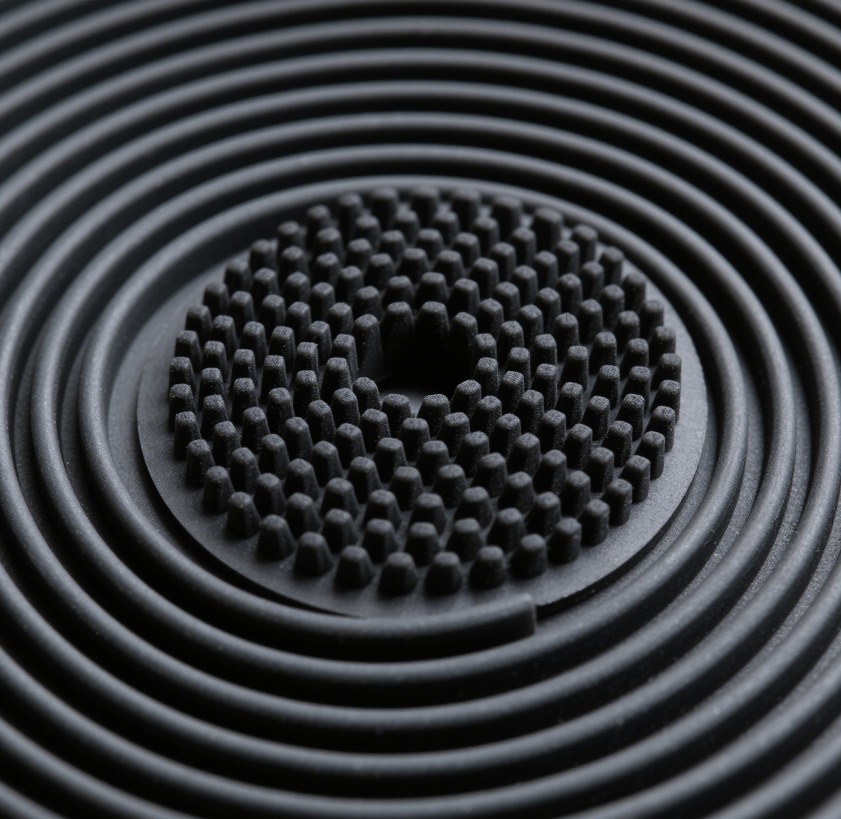

IV. Structural Design and Optimization

(1) Multilayer Composite Structure

A three-layer composite structure is designed: the outer layer is compounded with low-dielectric-constant silicone rubber and a small amount of carbon nanotubes (with a mass fraction of 2%) to match the air impedance and reduce the reflection of electromagnetic waves; the middle layer is filled with a high-content composite wave-absorbing filler (the total content of carbonyl iron powder and carbon nanotubes is 30%) to achieve the main electromagnetic absorption; the inner layer is added with FSS functional fillers to carry out resonant absorption for specific frequency bands. By adjusting the thickness of each layer (the outer layer is 0.5mm, the middle layer is 1.5mm, and the inner layer is 0.3mm), the overall impedance matching is optimized, and the wave-absorbing frequency band is broadened.

(2) Gradient Structure

A gradient-structured wave-absorbing silicone rubber with gradually changing electromagnetic parameters along the thickness direction is prepared. From the surface to the inside of the material, the content of the magnetic filler is gradually increased (for example, from 10% on the surface to 30% inside), so that the magnetic permeability and dielectric constant of the material change in a gradient manner, realizing the progressive absorption of electromagnetic waves of different frequencies and further improving the broadband wave-absorbing performance.

V. Optimization of the Preparation Process

(1) Mixing Process

A two-roll mill is used for mixing. First, the vinyl silicone rubber is passed thinly 5 times at a roll temperature of 60°C, and then the wave-absorbing filler treated with the coupling agent, the plasticizer, and the vulcanizing agent are added in turn. The mixing time is controlled to be 15 – 20 minutes to ensure the uniform dispersion of the filler and avoid the influence of local concentration differences on the wave-absorbing performance.

(2) Vulcanization Process

The vulcanization is carried out by hot pressing, the vulcanization temperature is set at 120°C, the pressure is 10MPa, and the vulcanization time is 15 minutes. The vulcanization conditions are precisely controlled to ensure that the silicone rubber forms a uniform and appropriate cross-linking network, which not only maintains the flexibility of the material but also provides a stable support structure for the wave-absorbing filler.

VI. Performance Testing and Evaluation

(1) Wave-Absorbing Performance Testing

A vector network analyzer is used, and the bow method is adopted to test the reflection loss of the sample in the frequency range of 2 – 18GHz. The bandwidth with a reflection loss of less than -10dB is used as the evaluation index of the broadband performance. At the same time, the maximum reflection loss value is analyzed to evaluate the wave-absorbing intensity.

(2) Mechanical Performance Testing

The tensile strength and elongation at break are tested according to the GB/T 528 – 2009 standard, and the tear strength is tested according to the GB/T 529 – 2008 standard to ensure that the material meets the mechanical requirements of practical applications while having excellent wave-absorbing performance.

(3) Environmental Adaptability Testing

The sample is placed in environments of high temperature (80°C), low temperature (-40°C), and high humidity (90% RH) for 24 hours respectively, and then the changes in its wave-absorbing performance and mechanical performance are tested to verify the environmental stability of the material.

VII. Conclusion

By analyzing the broadband wave-absorbing mechanism, reasonably selecting the matrix, filler, and additives, and optimizing the material structure and preparation process, a broadband wave-absorbing silicone rubber with excellent performance can be developed. The composite filler system, multilayer composite and gradient structure design, and process optimization method proposed in this scheme provide a technical route for the development of broadband wave-absorbing silicone rubber. In the follow-up, the material performance can be further improved through experimental verification and parameter adjustment, and its application in fields such as electronic communication and national defense and military industry can be promoted.

This scheme focuses on the development of broadband wave-absorbing silicone rubber and covers multiple aspects. If you have any questions about a certain link or want to adjust the development direction, you can let us know at any time.