Application of Wave Absorbing Silicone Rubber in Stealth Technology

2025/04/18

0

I. Introduction

I. Introduction

In the fields of modern military and high-end technology, stealth technology is the key to enhancing the survivability and combat effectiveness of equipment. The core of stealth technology lies in reducing the detectability of the target. Wave absorbing materials can effectively absorb and attenuate incident electromagnetic waves, reducing the radar reflection signals of the target, and are an important means to achieve stealth. Wave absorbing silicone rubber combines the excellent physical and chemical properties of silicone rubber with wave absorbing functions. It has the characteristics of good flexibility, strong weather resistance, and convenient processing and molding, showing great application potential in stealth technology. This article will discuss in detail the application scenarios, performance advantages, challenges faced, and coping strategies of wave absorbing silicone rubber in stealth technology.

II. Performance Advantages of Wave Absorbing Silicone Rubber

(I) Good Wave Absorbing Performance

By reasonably selecting wave absorbing fillers (such as magnetic materials, carbon-based materials and their composites) and optimizing the formulation, wave absorbing silicone rubber can achieve efficient wave absorption within a wide frequency range. For example, when carbonyl iron powder and carbon nanotubes are compounded and filled into silicone rubber in a certain proportion, in common radar frequency bands such as the X band (8 – 12GHz) and the Ku band (12 – 18GHz), it can effectively absorb electromagnetic waves, making the reflection loss reach below -20dB, and significantly reducing the radar cross section (RCS) of the target.

(II) Excellent Physical and Chemical Properties

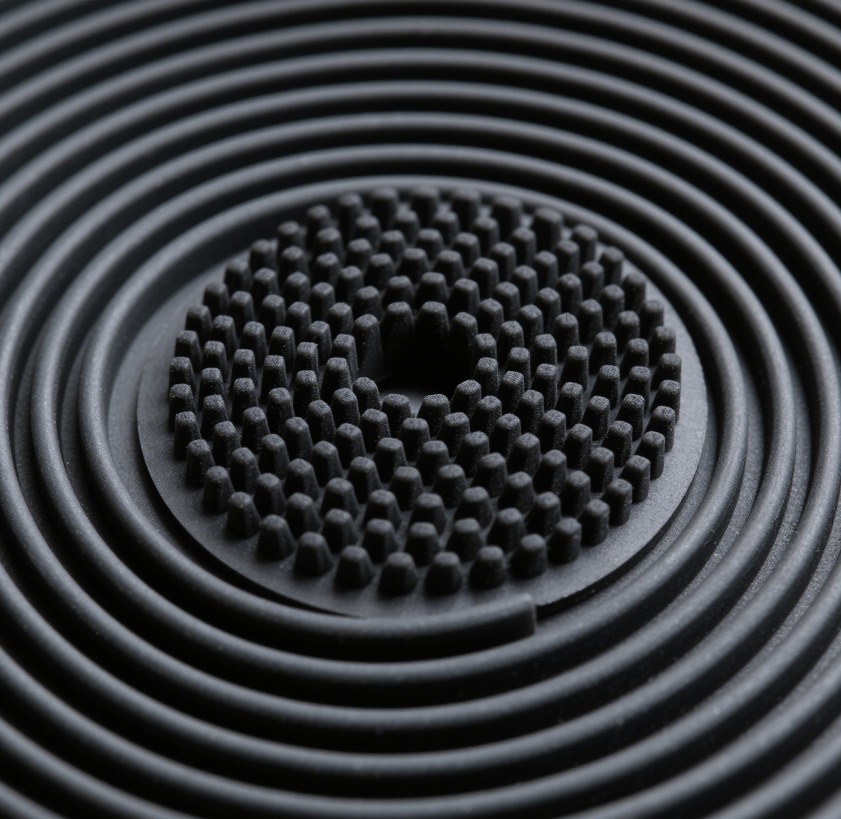

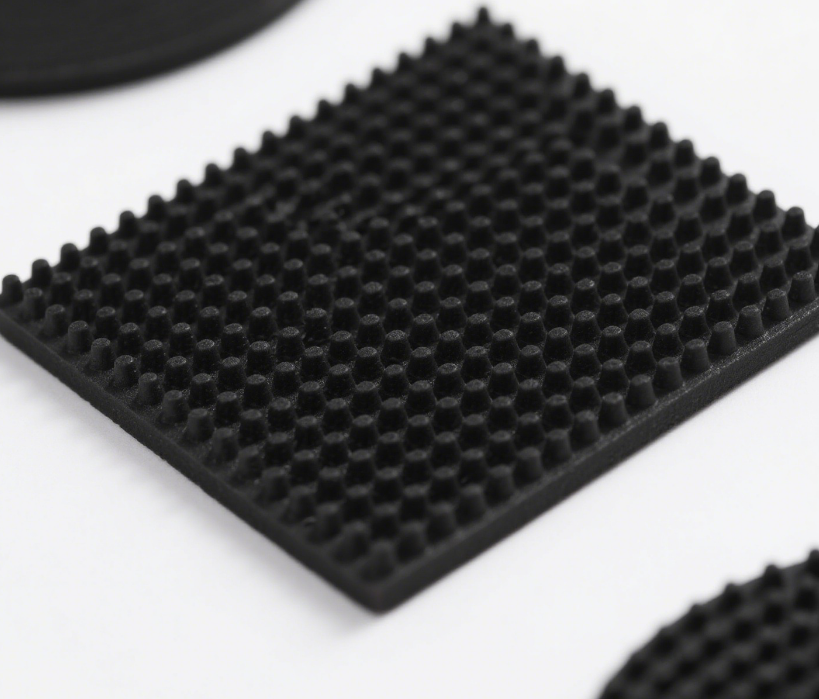

- Flexibility and Processability: Silicone rubber itself has good flexibility, and this property can still be maintained after being made into a wave absorbing material. It can be molded through various processing techniques such as compression molding, extrusion, and injection, and can meet the requirements of stealth components with complex shapes, such as fitting the curved surfaces of aircraft wings and fuselages.

- Weather Resistance and Environmental Adaptability: Wave absorbing silicone rubber has excellent high and low temperature resistance (it can be used for a long time in an environment of -60°C to 200°C), aging resistance, and corrosion resistance. Whether in harsh environments such as high temperature, low temperature, high humidity, salt spray, or ultraviolet radiation, it can maintain stable wave absorbing performance and physical properties, ensuring the reliable operation of stealth equipment in different environments.

(III) Multifunctional Integration

Some wave absorbing silicone rubbers can achieve the integration of wave absorbing performance and other functions by adding special functional additives. For example, adding microcapsules with self-healing functions enables the wave absorbing silicone rubber to automatically repair after being slightly damaged, maintaining its stealth performance; adding thermal conductive fillers can improve the thermal conductivity of the material to meet the heat dissipation requirements of internal electronic components of stealth equipment without affecting the wave absorbing effect.

III. Application Scenarios in Stealth Technology

(I) Aerospace Field

- Stealth Skin of Aircraft: Using wave absorbing silicone rubber as the stealth skin material on the surfaces of aircraft, missiles, and other aircraft can effectively absorb radar waves, reduce the RCS of the aircraft, and improve its stealth performance. Its flexibility and processability can perfectly fit the complex curved surface shapes of the aircraft, and it has strong weather resistance, adapting to the extreme environments during high-altitude and high-speed flights.

- Stealth Treatment of the Engine Compartment: The engine compartment is one of the strong reflection sources of the aircraft. Wave absorbing silicone rubber can be used for the stealth treatment of the inner wall of the engine compartment, the air intake duct, and other parts, absorbing the electromagnetic radiation generated during the operation of the engine, reducing the radar reflection signals, and at the same time playing the roles of heat insulation and noise reduction.

(II) Ground Equipment Field

- Stealth Coatings for Tanks and Armored Vehicles: Coating wave absorbing silicone rubber coatings on ground equipment such as tanks and armored vehicles can reduce their visibility under radar detection and improve their battlefield survivability. This coating has good wear resistance and impact resistance, and can adapt to the complex driving environments of ground equipment.

- Stealth Protection of Communication Equipment: Using wave absorbing silicone rubber materials for stealth protection on the surfaces of military communication base stations, radar stations, and other equipment can reduce the electromagnetic radiation leakage of the equipment itself, avoid being detected by the enemy, and at the same time protect the equipment from external electromagnetic interference, ensuring the accuracy of communication and detection.

(III) Marine Equipment Field

- Stealth Covering of Submarines: When a submarine is sailing underwater, it needs to avoid being detected by the enemy’s sonar and radar. Wave absorbing silicone rubber can be used for the stealth covering of the submarine’s hull, absorbing radar waves and reducing reflection signals. At the same time, its good water resistance and corrosion resistance can adapt to the high-salt and high-pressure marine environment.

- Stealth Materials for Underwater Vehicles: For marine equipment such as unmanned underwater vehicles, wave absorbing silicone rubber can be used as a stealth material, reducing the probability of being detected during underwater activities and improving the concealment and safety of mission execution.

IV. Challenges and Solutions

(I) Balancing Wave Absorbing Performance and Mechanical Properties

When improving the wave absorbing performance of wave absorbing silicone rubber, it is often necessary to increase the content of wave absorbing fillers. However, excessive addition will lead to a decline in the mechanical properties of the material, such as increased hardness, reduced flexibility, and decreased tensile strength.

- Solutions: Develop new wave absorbing fillers, such as nanocomposites with high wave absorbing efficiency, to achieve efficient wave absorption at a low addition amount; optimize the surface treatment process of the fillers to enhance the interfacial bonding force between the fillers and the silicone rubber matrix and improve the mechanical properties of the material; adopt a gradient structure design to reasonably distribute the filler content under the premise of ensuring the wave absorbing performance and improve the mechanical properties of the material.

(II) Cost and Mass Production

Some high-performance wave absorbing fillers (such as carbon nanotubes, graphene, etc.) in wave absorbing silicone rubber are costly and have complex preparation processes, which limit their large-scale application.

- Solutions: Explore low-cost preparation methods for wave absorbing fillers, such as using industrial waste to prepare magnetic materials; optimize the production process, improve production efficiency, and reduce production costs; develop universal wave absorbing silicone rubber formulations to meet the needs of different stealth scenarios and achieve large-scale production.

(III) Durability of Stealth Performance

During long-term use, wave absorbing silicone rubber may be affected by environmental factors (such as ultraviolet rays, salt spray, high temperature, etc.), resulting in a decline in wave absorbing performance and a weakening of the stealth effect.

- Solutions: Add anti-aging and anti-corrosion additives to improve the environmental resistance of the material; carry out surface protection treatment on the wave absorbing silicone rubber, such as coating a protective layer to isolate the erosion of the external environment on the material; develop wave absorbing silicone rubber with self-healing functions to timely repair the performance damage caused by environmental factors and extend the service life of the stealth material.

V. Conclusion

Wave absorbing silicone rubber has a wide application prospect in stealth technology due to its unique performance advantages. Although there are currently challenges in performance balance, cost control, and stealth durability, these problems will be gradually solved through continuous technological innovation and process improvement. In the future, with the continuous improvement of the requirements for stealth technology, wave absorbing silicone rubber is expected to play a more important role in the military, aerospace, marine, and other fields, promoting the further development of stealth technology.

The above content elaborates in detail on the application of wave absorbing silicone rubber in stealth technology. If you want to have an in-depth understanding of a certain application scenario or discuss relevant technical details, you can communicate with me at any time.