Application of Wave-Absorbing Silicone Rubber in the Field of Electromagnetic Compatibility

2025/04/18

0

I. Introduction

I. Introduction

With the rapid development of electronic information technology, the number and density of electronic devices have increased sharply. Electromagnetic interference (EMI) and electromagnetic radiation problems have become increasingly serious. Electromagnetic compatibility (EMC) has become a key field for ensuring the normal operation of electronic devices and maintaining information security. As a material that combines wave-absorbing functions with the excellent properties of silicone rubber, wave-absorbing silicone rubber shows unique advantages in the field of electromagnetic compatibility. It can effectively absorb and attenuate electromagnetic waves, reduce electromagnetic interference, and provide a good electromagnetic environment for electronic devices. This article will deeply explore the application scenarios, performance advantages, challenges faced, and coping strategies of wave-absorbing silicone rubber in the field of electromagnetic compatibility.

II. Performance Advantages of Wave-Absorbing Silicone Rubber

(1) High-Efficiency Wave-Absorbing Performance

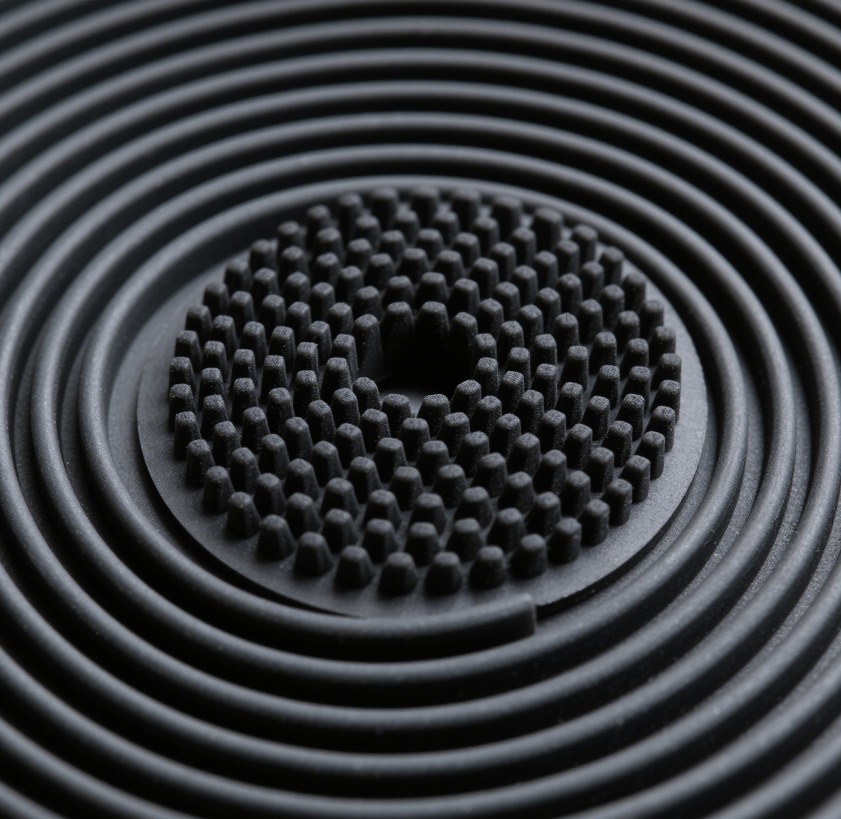

By reasonably blending wave-absorbing fillers (such as magnetic materials, carbon-based materials, and their composites), wave-absorbing silicone rubber can achieve high-efficiency absorption of electromagnetic waves within a wide frequency range. For example, when carbonyl iron powder is compounded with graphene and filled into silicone rubber, within the frequency range of 1 – 18GHz, it can effectively absorb electromagnetic waves in different frequency bands, making the reflection loss reach below -15dB, significantly reducing the intensity of electromagnetic interference and creating a low-electromagnetic interference working environment for electronic devices.

(2) Excellent Physical and Chemical Properties

- Flexibility and Processability: The good flexibility of silicone rubber endows wave-absorbing silicone rubber with excellent deformation ability, enabling it to be formed through various processes such as compression molding, extrusion, and injection molding. It can meet the requirements of complex-shaped components in electronic devices, such as irregular circuit board edges and narrow interface parts, achieving a tight fit and effectively suppressing electromagnetic leakage.

- Weather Resistance and Stability: Wave-absorbing silicone rubber has excellent high and low-temperature resistance (it can work stably in the environment of -60℃ – 200℃), aging resistance, and chemical stability. In different temperature and humidity environments, as well as during long-term use, its wave-absorbing performance and physical properties are not prone to significant attenuation, and it can continuously provide reliable electromagnetic compatibility protection for electronic devices.

(3) Good Insulation and Compatibility

Wave-absorbing silicone rubber itself has good electrical insulation performance and will not cause adverse effects such as short circuits on the circuits of electronic devices. At the same time, it has good compatibility with commonly used materials in electronic devices, such as plastics and metals. It can be closely combined with other components through coating, pasting, and other methods, making it convenient for flexible application in electromagnetic compatibility design.

III. Application Scenarios in the Field of Electromagnetic Compatibility

(1) Internal Shielding of Electronic Devices

- Circuit Board Shielding: Coating a wave-absorbing silicone rubber coating on the surface of the circuit board, or using wave-absorbing silicone rubber gaskets and pads to encapsulate the circuit board can effectively absorb the electromagnetic radiation generated by the electronic components on the circuit board, prevent the electromagnetic interference from spreading to the surrounding space, and at the same time block the influence of external electromagnetic interference on the circuit board, improving the stability of the circuit and the quality of signal transmission. For example, in high-speed digital circuit boards, wave-absorbing silicone rubber can suppress signal crosstalk and reduce the bit error rate.

- Electronic Component Encapsulation: For some electronic components with strong electromagnetic radiation, such as power amplifiers and oscillators, using wave-absorbing silicone rubber for encapsulation can limit the electromagnetic radiation they generate within a certain range and avoid interference with other components. At the same time, the insulation performance of wave-absorbing silicone rubber can also play a role in protecting the components and prevent the components from being damaged due to electromagnetic interference.

(2) Equipment Shell and Interface Protection

- Shell Shielding: Pasting or coating wave-absorbing silicone rubber materials on the inner wall of the electronic device shell can absorb the electromagnetic radiation generated inside the device, reduce the electromagnetic leakage to the outside world, and make the device meet the requirements of electromagnetic compatibility standards. For some occasions that are sensitive to electromagnetic radiation, such as medical devices and communication base stations, the wave-absorbing silicone rubber shell can effectively reduce the electromagnetic pollution of the device to the surrounding environment.

- Interface Sealing: The interfaces of electronic devices (such as USB interfaces, network interfaces, etc.) are important channels for electromagnetic leakage. Using wave-absorbing silicone rubber seals to seal the interfaces can not only prevent electromagnetic waves from leaking from the interfaces but also play the roles of waterproofing and dustproofing, improving the reliability and service life of the device.

(3) Communication and Data Centers

- Communication Base Station Protection: In communication base stations, a large number of devices such as antennas, transmitters, and receivers will generate strong electromagnetic radiation, and they are also easily affected by external electromagnetic interference. Wave-absorbing silicone rubber can be used for the shielding and protection of base station equipment, reducing the mutual interference between devices and improving the quality and stability of communication signals. For example, using wave-absorbing silicone rubber materials on the protective covers of base station antennas can reduce the backward radiation of the antennas and reduce the impact on the surrounding environment.

- Electromagnetic Protection in Data Centers: Servers, storage devices, etc. are densely arranged in data centers, and the electromagnetic environment is complex. Wave-absorbing silicone rubber can be used for the electromagnetic shielding of the walls, ceilings, and floors of the computer room, reducing the impact of electromagnetic interference on the devices and ensuring the safe transmission and storage of data. In addition, using wave-absorbing silicone rubber materials inside the server cabinets can also reduce the electromagnetic radiation generated by the devices themselves and improve energy utilization efficiency.

IV. Challenges and Solutions

(1) Balancing Wave-Absorbing Performance and Cost

High-performance wave-absorbing fillers (such as carbon nanotubes, MXene, etc.) are expensive, resulting in a high cost of wave-absorbing silicone rubber, which limits its large-scale application.

- Solutions: Develop low-cost wave-absorbing fillers, such as preparing magnetic wave-absorbing materials using natural mineral resources; optimize the formulation design, and by reasonably combining different types of wave-absorbing fillers, reduce the usage amount of high-performance fillers while ensuring the wave-absorbing performance; explore new preparation processes, improve production efficiency, and reduce production costs.

(2) Adaptability to Complex Electromagnetic Environments

The electromagnetic environments of different electronic devices and application scenarios vary greatly, and a single formulation of wave-absorbing silicone rubber is difficult to meet all requirements.

- Solutions: Establish a performance database of wave-absorbing silicone rubber, and design targeted formulations and structures according to different electromagnetic environment parameters (such as frequency range, field strength, etc.). Adopt the modular design concept and develop combinable and adjustable wave-absorbing silicone rubber products to meet the needs of different complex electromagnetic environments.

(3) Long-Term Use Performance Stability

During long-term use, wave-absorbing silicone rubber may be affected by factors such as temperature, humidity, and mechanical vibration, resulting in a decrease in wave-absorbing performance.

- Solutions: Add anti-aging and anti-fatigue additives to improve the environmental resistance and mechanical stability of wave-absorbing silicone rubber. Carry out surface protection treatment on wave-absorbing silicone rubber, such as coating a protective layer, to enhance its resistance to environmental erosion. Regularly detect and maintain the devices using wave-absorbing silicone rubber, and replace the components with degraded performance in a timely manner.

V. Conclusion

Wave-absorbing silicone rubber has broad application prospects in the field of electromagnetic compatibility due to its high-efficiency wave absorption, excellent physical and chemical properties, and other characteristics. Although it currently faces challenges such as cost, adaptability, and performance stability, these problems will be gradually solved through technological innovation and process improvement. In the future, with the continuous development of electronic information technology and the increasing requirements for electromagnetic compatibility, wave-absorbing silicone rubber is expected to play an important role in more fields and provide strong support for the reliable operation of electronic devices and information security.

The above content comprehensively introduces the application of wave-absorbing silicone rubber in the field of electromagnetic compatibility. If you want to have an in-depth understanding of a certain application scenario or discuss specific technical issues, you can communicate with me at any time.