conductive rubber for wearable devices

2025/04/17

0

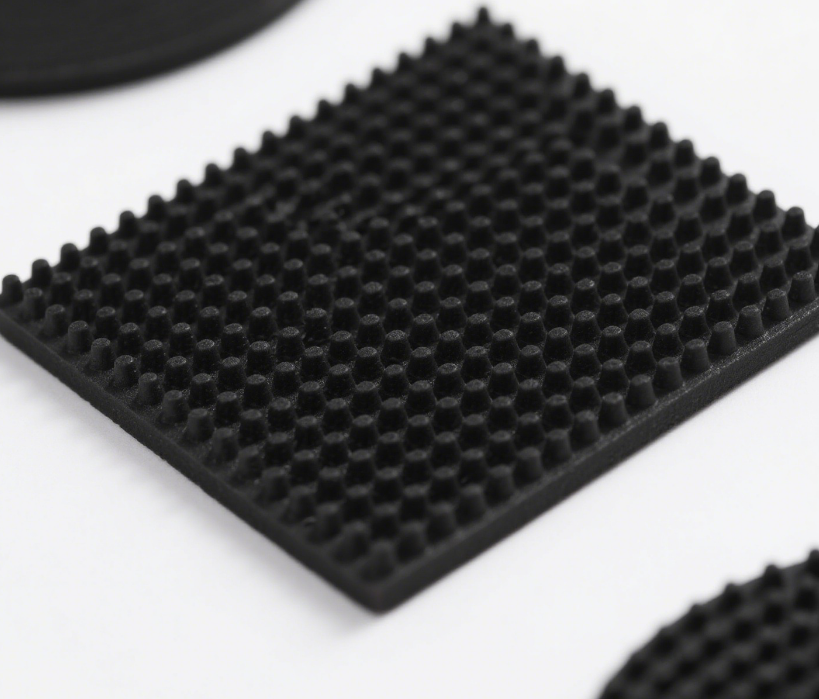

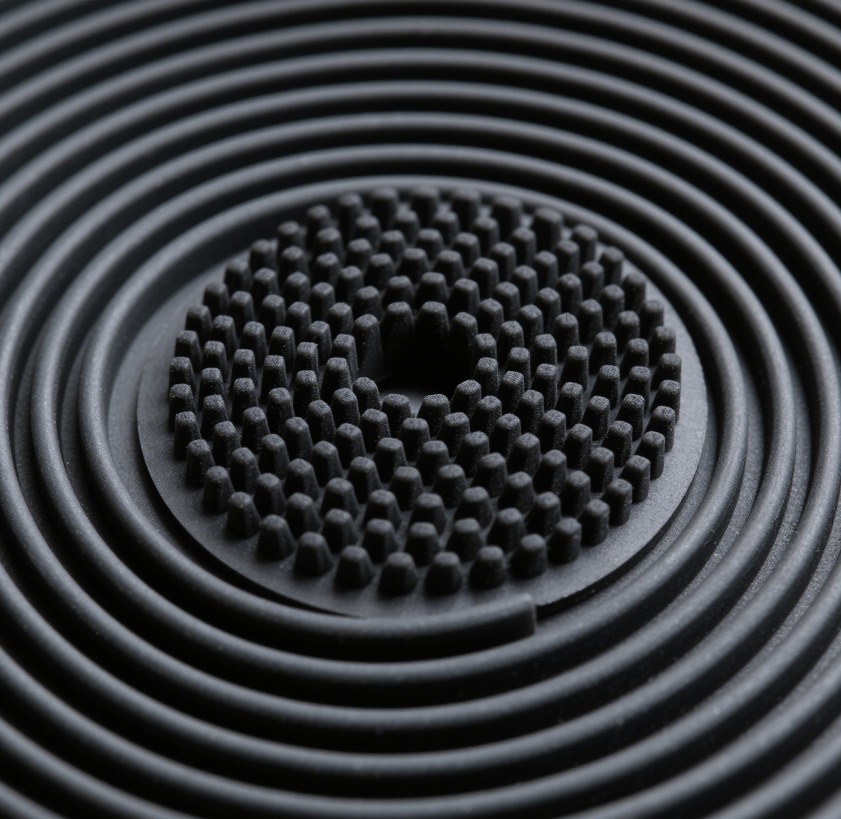

The conductive rubber in wearable devices is a functional material that combines the flexibility of rubber with electrical conductivity. Its core lies in the composite of conductive fillers (such as graphene, silver-plated particles, carbon black, etc.) and the rubber matrix to achieve functions such as signal transmission, electromagnetic shielding, and flexible sensing. The following analysis will be carried out from material characteristics, application scenarios, technological progress, and future trends:

The conductive rubber in wearable devices is a functional material that combines the flexibility of rubber with electrical conductivity. Its core lies in the composite of conductive fillers (such as graphene, silver-plated particles, carbon black, etc.) and the rubber matrix to achieve functions such as signal transmission, electromagnetic shielding, and flexible sensing. The following analysis will be carried out from material characteristics, application scenarios, technological progress, and future trends:

- Material Characteristics and Classification

- Matrix Materials

Silicone rubber: The most commonly used matrix, which has excellent resistance to high and low temperatures (-65°C to 200°C), aging resistance, and biocompatibility, and is suitable for medical-grade devices (such as the electrodes of smart bracelets).

· Fluororubber: Resistant to chemical corrosion, and is often used in sports equipment that requires waterproofing, such as fluororubber watchbands. - Conductive Fillers

Metal-based: Silver, copper, and silver-plated aluminum particles have excellent electrical conductivity (with a volume resistivity as low as 0.002 Ω・cm), but the cost is relatively high.

· Carbon-based materials: Graphene and carbon black have a lower cost and can improve the mechanical strength. With the enhancement of graphene, the tensile strength can be increased by 100 times.

· Nanomaterials: Carbon nanotubes can form a continuous conductive network, and the gel electrodes have both electrical conductivity and biocompatibility. - Performance Parameters

Electrical conductivity: The volume resistivity ranges from 0.002 Ω・cm (filled with pure silver) to 10⁶ Ω・m (piezoresistive sensors), and the shielding effectiveness can reach up to 120 dB (10 GHz).

· Mechanical properties: The tensile strength is 1.38-3.80 MPa, the elongation at break is 75%-200%, and it can withstand a deformation of more than 200%.

· Environmental adaptability: Resistant to salt spray, acids, and alkalis. Some materials (such as fluororubber) can work stably at temperatures ranging from -55°C to 170°C. - Core Application Scenarios

- Flexible Sensors

Pressure and strain monitoring: Graphene composite rubber is used in flexible piezoresistive sensors, which can monitor human motion postures in real time (such as smart insoles).

· Health monitoring: Conductive rubber electrodes are used for heart rate and electromyogram detection, such as the ECG electrodes of medical-grade smart bracelets. - Electromagnetic Shielding and Sealing

Smartwatches and headphones: Silver-plated aluminum conductive rubber sealing gaskets prevent electromagnetic interference (EMI) and achieve waterproof sealing at the same time.

· 5G devices: Silicone rubber electromagnetic shielding tubes are used for high-frequency signal transmission (such as 5G base station antennas). - Flexible Circuits and Connectors

Zebra strips: Alternately layered conductive/insulating rubber is used for connecting liquid crystal displays and circuit boards (such as in electronic watches and calculators).

· 3D printed electrodes: Customizable geometric shapes are available, and they are used in implantable medical devices. - Energy Management

Triboelectric nanogenerators: They can convert mechanical energy into electrical energy and are used in self-powered wearable devices.