01 Product Introduction

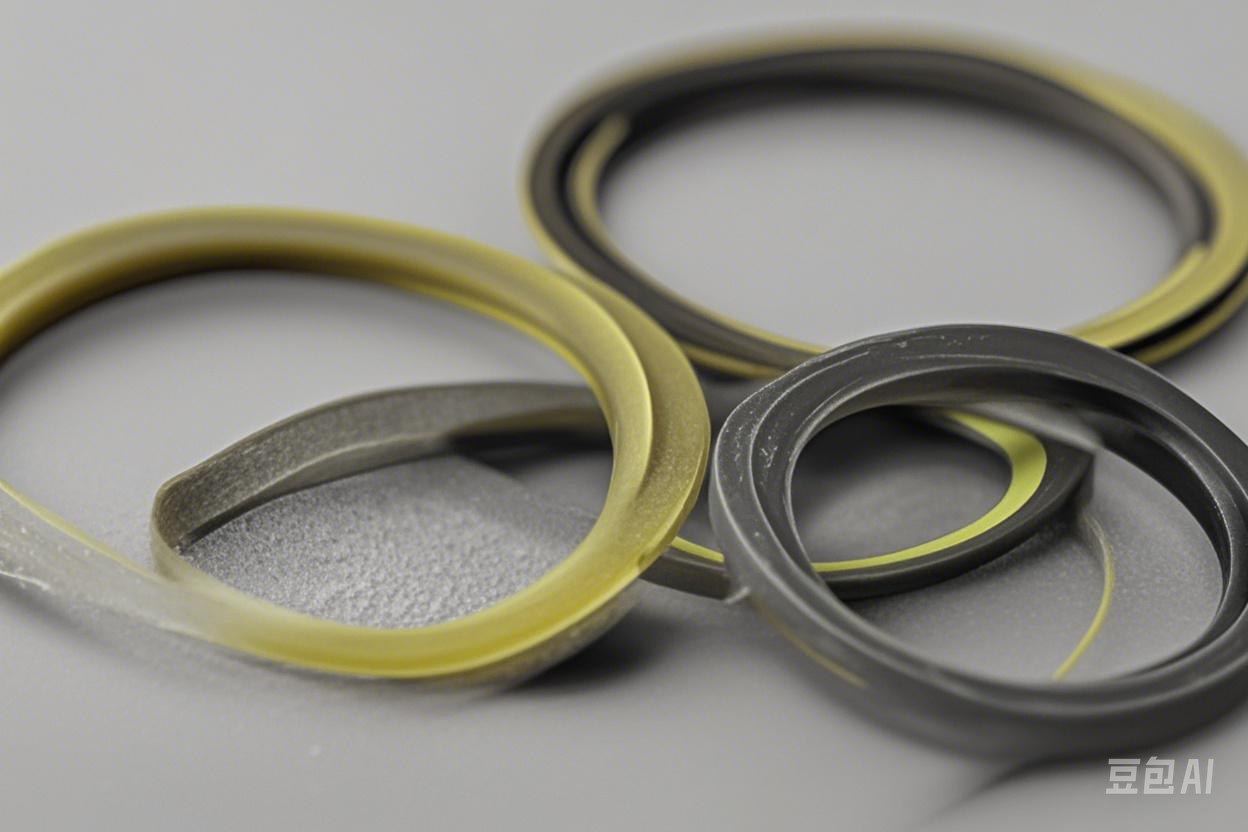

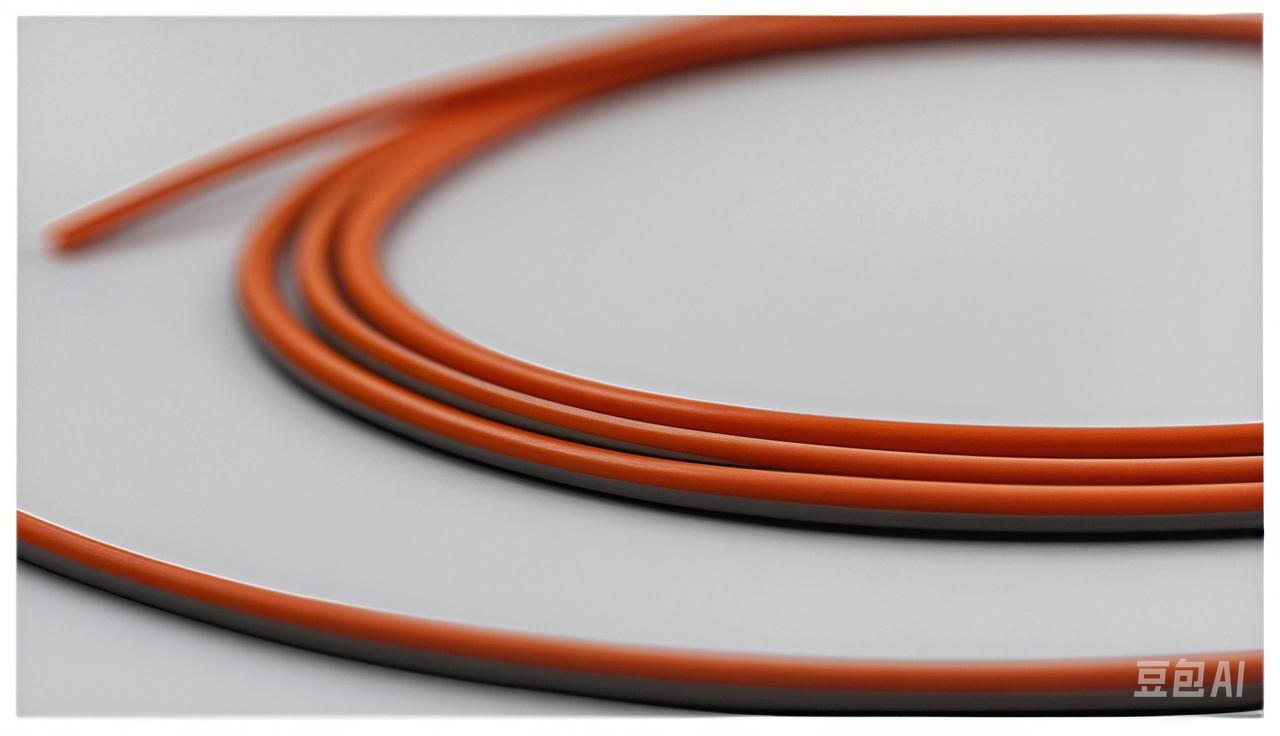

The E-Coating conductive rubber with the primer coating process is a kind of conductive rubber with special process and structure, which is very suitable for the application of small-sized extruded rubber strips. Its high conductivity and thin conductive layer not only have a high level of EMI shielding effectiveness but also possess good electrochemical stability. The unique primer coating process can ensure the wear resistance, corrosion resistance reliability of the surface coating, as well as the uniform and consistent aesthetic characteristics. The inner core of the E-Coating conductive rubber with the primer coating process is a non-conductive elastomer, which still has good compression and rebound characteristics even in the case of a very small size. It is an excellent choice for the environmental sealing and electromagnetic shielding of products with small sizes and compact structures. The cost of the non-conductive elastomer is much lower than that of the conductive elastomer. At the same time, the metal coating on the surface of the product is very thin. Therefore, the E-Coating product is also very competitive in terms of cost in the market.

NQ-C6001 has an Ag/AI conductive layer coated on its surface. It is firmly combined with the inner non-conductive rubber through the primer coating process and is not prone to powder shedding. It is mainly applied to industries such as high-speed connectors, optical modules, and radio frequency modules.

02Product Features

• The elastic inner layer does not contain metallic fillers, ensuring optimal compression performance and aging performance.

• The conductive particles are only present in the outer coating layer, thus having excellent electrical conductivity.

• The ultra-thin conductive layer significantly reduces the required silver content.

• Through a special coating process, it effectively saves the cost of precious metals without reducing the electrical conductivity and shielding performance.

• Compared with elastomers fully filled with solid materials, the attenuation performance does not decrease under full compression force.

• Extremely low compression force and strong anti-deformation ability.

• Due to the flexibility in manufacturing and the rapid response to customer customization, an effective alternative solution can be provided within a very short period of time.

• The cross-sectional shape can be customized according to customer requirements.

03Product Applications

• Base stations

• High-speed connectors & high-speed optical modules

• Small radio frequency modules

• Telecommunications

• Portable wearable devices